Welcome to Dhingra Scotways

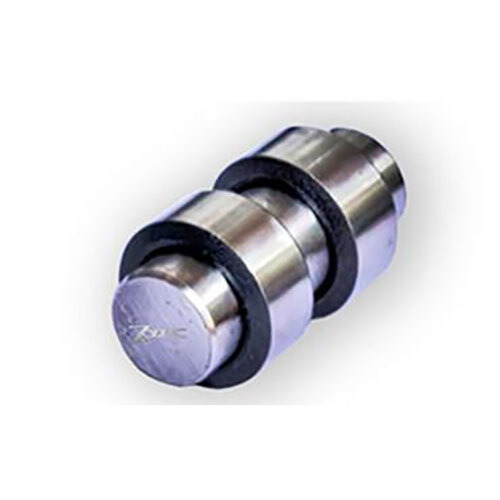

Idler gear

100-10000 INR/Piece

Product Details:

- Connecting Type Keyed or Splined Shaft

- Material Alloy Steel

- Model No IG-4021

- Lubrication Type Grease / Oil Lubrication

- Corrosion Resistant Yes (with surface treatment)

- For Use In Industrial Machinery, Automotive Applications

- Dimension (L*W*H) Standard / Custom sizes available

- Click to view more

X

Idler gear Price And Quantity

- 100 Piece

- 100-10000 INR/Piece

- CNC Turning and Hobbing

- Corrugated Box / Wooden Case

- Low, periodic lubrication required

- Bored / Hub / Shaft Mounted

- Used in gear trains to transfer motion and reduce gear mesh attrition

- 58-62 HRC (after hardening)

- 18 36

Idler gear Product Specifications

- Transmission Gear

- Smooth / Machined

- Alloy Steel

- Precision Machining

- Keyed or Splined Shaft

- Up to 30,000 operational hours

- Yes (with surface treatment)

- Up to 2000 kg

- Industrial Machinery, Automotive Applications

- Case Hardened, Polished

- IG-4021

- Grease / Oil Lubrication

- Standard / Custom sizes available

- Silver / Metallic Grey

- -20C to 150C

- Idler Gear

- Commercial Vehicles, Industrial Conveyors

- Approx. 1.5 - 3.5 kg

- Low (<60 dB)

- Module 2.5 ~ 4.5, Diameter 80 200 mm

- Mechanical Drive System

- CNC Turning and Hobbing

- Corrugated Box / Wooden Case

- Low, periodic lubrication required

- Bored / Hub / Shaft Mounted

- Used in gear trains to transfer motion and reduce gear mesh attrition

- 58-62 HRC (after hardening)

- 18 36

Idler gear Trade Information

- 1000 Piece Per Day

- 30 Days

Product Description

Idler gear is the gear positioned between the input and output shafts (between the drive gear and the driven gear). It can be used, for instance, to alter the output shaft's direction of rotation or to bridge a significant gap between the input and output shafts without changing the speed ratio. In addition to this, the said product is used in gear trains to ensure that the output shaft rotates in the desired direction. Idle gear should be noticed that both the driver and driven or follower gears move similarly when the number of intermediate gears is odd.Robust Construction and Performance

Made using high-grade alloy steel and treated for superior hardness (5862 HRC), the Idler Gear IG-4021 demonstrates excellent durability and wear resistance. The case-hardened, polished surface enhances longevity, while its smooth machined finish ensures quiet and efficient operation even under heavy loads and extended use.

Versatile Applications

This idler gear fits seamlessly into a broad spectrum of gear trains in industrial machinery, commercial vehicles, and conveyor systems. Thanks to its adaptable mounting types and keyed or splined shaft connections, it is suitable for both new installations and as a replacement in mechanical drive systems.

Precision Engineering

Manufactured using state-of-the-art CNC turning and hobbing processes, the gear achieves precise module sizes (2.5 ~ 4.5) and diameters (80200 mm). This precision ensures compatibility with custom or standard setups and provides consistent, low-noise performance (below 60 dB) with minimal vibration.

FAQs of Idler gear:

Q: How is the Idler Gear IG-4021 installed or mounted?

A: The Idler Gear IG-4021 can be mounted in several ways: using a bored, hub, or shaft-mounted setup. It connects securely through keyed or splined shafts, allowing for straightforward installation in various transmission systems and mechanical drive configurations.Q: What maintenance does the gear require to ensure long operational life?

A: This idler gear is designed for low-maintenance operation. Periodic lubrication using grease or oil is recommended to reduce wear and ensure smooth movement. Under proper maintenance, the gear delivers up to 30,000 operational hours.Q: Where can this idler gear be used, and what benefits does it offer?

A: It is ideal for use in industrial machinery and commercial vehicles, particularly within gear trains to transfer motion and minimize gear mesh attrition. Its robust build and precisely machined finish promote consistent performance, low noise, and extended service life, making it a valuable component in transmission systems.Q: What is the manufacturing process used for this idler gear?

A: The IG-4021 idler gear is manufactured through precision CNC turning and hobbing. These advanced techniques ensure tight tolerances, accurate tooth profiles, and a smooth machined finish, culminating in consistently reliable gears for heavy-duty applications.Q: How does the surface treatment benefit the gears performance and longevity?

A: Case hardening and polishing significantly enhance the gears resistance to wear, corrosion, and fatigue. This surface treatment contributes to the extended working life and continued low-maintenance operation in tough industrial environments and automotive applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email